I went to replace the seals in the old Delta faucet in our bath/shower, somehow I managed to mess it up and water was leaking behind the wall afterwards. The drip from the faucet was gone though!

I guess I forgot to take a pic of how it looked before but this was after cutting out the supports for the old diverter/temp valve and bath faucet.

Heres with the new supports put in and the pipe connected to the shower head and tub faucet, still need to run the hot/cold water pipe to it.

Here's the part that goes through the wall to the tub faucet. Once it's through I glued a threaded fitting on that the tub faucet screws onto.

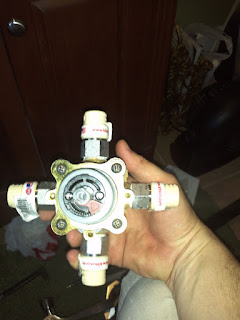

Here's the new valve with fittings, the owners before us put the shower head, tub faucet and escutcheon on but left the old valve in. After doing this I know why! The nice thing with this new valve is that you can control the temp and pressure separately, all you have to do is set it to the temp you like and turn the shower on and off, it will always stay at that temp which is nice.

Here it is almost ready.

All done except the handle.